Chimiro

Zvigadzirwa

Din 1.4404 / aisi 316l, din 1.4539 / aisi 904l

Malel, inconel, Duckles Simbi, Kukurumidza Alloys

Zvimwe zvinhu zvinowanikwa pachikumbiro.

Filter Fineness: 1 -100 Microns

Zvinyorwa

| Spection -Rekumarakiti mashanu-danda rinotakura mesh | ||||||||

| Tsanangudzo | Filter fineeness | Chimiro | Ukobvu | Porosity | Mhepo YEMAHARA | Rp | Uremu | Bubble kumanikidza |

| μm | mm | % | (L / min / cm²) | N / cm | kg / ㎡ | (mmh₂o) | ||

| SSM-F-1 | 1 | 100 + 400x2800 + 100 + 12/64 + 64/12 | 1.7 | 37 | 1.82 | 1080 | 8.4 | 360-600 |

| SSM-F-2 | 2 | 100 + 325X2300 + 100 + 12/64 + 64/12 | 1.7 | 37 | 2.36 | 1080 | 8.4 | 300-590 |

| SSM-F-5 | 5 | 100 + 200x1400 + 100 + 12/64 + 64/12 | 1.7 | 37 | 2.42 | 1080 | 8.4 | 260-550 |

| SSM-F-10 | 10 | 100 + 165X1400 + 100 + 12/64 + 64/12 | 1.7 | 37 | 3.08 | 1080 | 8.4 | 220-500 |

| SSM-F-15 | 15 | 100 + 165x1200 + 100 + 12/64 + 64/12 | 1.7 | 37 | 3.41 | 1080 | 8.4 | 200-480 |

| SSM-F-20 | 20 | 100 + 165x800 + 100 + 12/64 + 64/12 | 1.7 | 37 | 4.05 | 1080 | 8.4 | 170-450 |

| SSM-F-25 | 25 | 100 + 165x600 + 100 + 12/64 + 64/12 | 1.7 | 37 | 6.12 | 1080 | 8.4 | 150-410 |

| SSM-F-30 | 30 | 100 + 400 + 100 + 12/64 + 64/12 | 1.7 | 37 | 6.7 | 1080 | 8.4 | 120-390 |

| SSM-F-40 | 40 | 100 + 325 + 100 + 12/64 + 64/12 | 1.7 | 37 | 6.86 | 1080 | 8.4 | 100-350 |

| SSM-F-50 | 50 | 100 + 250 + 100 + 12/64 + 64/12 | 1.7 | 37 | 8.41 | 1080 | 8.4 | 90-300 |

| SSM-F-75 | 75 | 100 + 200 + 100 + 12/64 + 64/12 | 1.7 | 37 | 8.7 | 1080 | 8.4 | 80-250 |

| SSM-F-100 | 100 | 100 + 150 + 100 + 12/64 + 64/12 | 1.7 | 37 | 9.1 | 1080 | 8.4 | 70-190 |

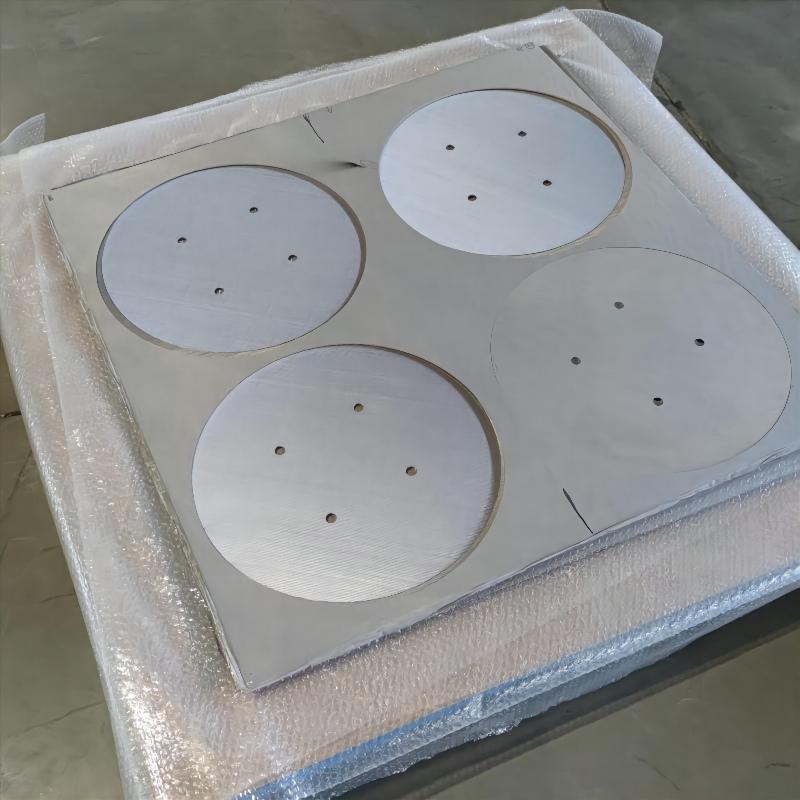

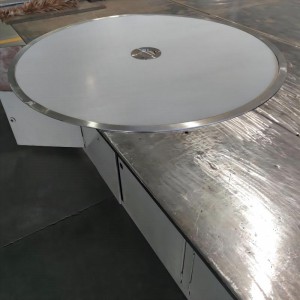

Saizi

DIAMETER: 5mm-1500mm

Yakakura kupfuura 1500mm, tinoda kupfava.

Zvishandiso

Yakaputika mibhedha, nziyo dzeNetsche, centrifuges, zasi kweSilos, zvinoshandiswa muBiotechnology.

Iyo yakajairwa mashanu-layer inotakura mesh chimiro chakakamurwa kuita zvikamu zvina: kuchengetedza dura, firita layer, kupararira layer uye skeleton layer. Rudzi urwu rwezvinyorwa zvefaira harisi chete yunifomu uye yakagadzikana filtration chaiyo asi zvakare ine simba rakanyanya uye kuomarara. Icho chinhu chakanakira chefaini yefaira yenzvimbo idzo dzisina yunifomu inodiwa. Nekuti magetsi aro emishini ari pamusoro peMavheti, uye iyo meshseri inotsvedza, ine yakanakisa yekudzokorora basa uye inogona kunyatsoenderana nekuenderera mberi uye otomatiki process matanho, iyo isina kugadzirwa neyese yefaira. Izvo zvinyorwa zviri nyore kuumba, ma teld, uye anogona kuongororwa mumhando dzakasiyana siyana dzezvishandiso zvakadai senge, cylindrical, concal and cany uye yakashatiswa.

hunhu

1. Kuwedzeredza kwakasimba uye kuomarara kwakanaka: ine simba rakasimba simba uye simba rekumanikidza, kugadzirisa kwakanaka, kutaridzika uye nyore kushandisa, uye nyore kushandisa.

2. Yunifomu uye yakagadzikana chaiyo: yunifomu uye yekufungidzira uye isingadzivisike pakubata inogona kuwanikwa kune ese magetsi ekutarisira, uye mesh haichinje panguva yekushandisa.

3

4. Zvakanakisa Kuchenesa Kuita

Iyo kambani ine International Advanced Zvigadzirwa Zvigadzirwa, Chikwata Chekutanga, Chikwata chehunyanzvi chehunyanzvi, kutengesa kwakashanda, uye yakakwana yebasa rebasa rekutengesa. Isu ticharamba tichivandudza yedu chaiyo mhando uye nhanho, uye rambai nezvishoma kusangana nezvinodiwa zvakasiyana zvevatengi zvine hunhu hwakanaka uye sevhisi yekufunga.