Chimiro

Zvigadzirwa

Din 1.4404 / aisi 316l, din 1.4539 / aisi 904l

Malel, inconel, Duckles Simbi, Kukurumidza Alloys

Zvimwe zvinhu zvinowanikwa pachikumbiro.

Filter Fineness: 1 -200 Microns

Zvinyorwa

| Kufunga - Punching Plate Inotadza Wire Mesh | ||||

| Tsanangudzo | Filter fineeness | Chimiro | Ukobvu | Porosity |

| μm | mm | % | ||

| SSM-P-1.5T | 2-100 | 60 + Filter layer + 60 + 30 + φ4x5px1.0t | 1.5 | 57 |

| SSM-P-2.0T | 2-100 | 30 + Filter layer + 30 + φ5x7px1.5t | 2 | 50 |

| SSM-P-2.5T | 20-100 | 60 + Filter layer + 60 + 30 + φ4x5px1.5t | 2,5 | 35 |

| SSM-P-3.0T | 2-200 | 60 + Filter layer + 60 + 20 + +6x8px2.0t | 3 | 35 |

| SSM-P-4.0T | 2-200 | 30 + Filter layer + 30 + 20 + +8x10px2.5t | 4 | 50 |

| SSM-P-5.0T | 2-200 | 30 + Filter layer + 30 + 20 + 16 + 10 + +8x10px3.0t | 5 | 55 |

| SSM-P-6.0T | 2-20 | 30 + Filter layer + 30 + 20 + 16 + 10 + φ8x10px4.0t | 6 | 50 |

| SSM-P-7.0T | 2-20 | 30 + Filter layer + 30 + 20 + 16 + 10 + +8x10px5.0t | 7 | 50 |

| SSM-P-8.0T | 2-20 | 30 + Filter layer + 30 + 20 + 16 + 10 + +8x10px6.0t | 8 | 50 |

| Iko ukobvu kweiyo kupuruzira ndiro uye chimiro cheaya waya mesh zvinogona kuve zvakagadzirirwa maererano nezvinodiwa nemushandisi. | ||||

Kutaura, kana ichishandiswa muzvivakwa zvechinyaradzo yekushambidza mweya, iyo faira remvura inogona kuve yakajairwa shanu-layer uye kupunha ndiro yakatakura pamwechete.

Iyo iri 100 + firita layer + 100 + 12/64 + 64/20

Iko ukobvu hwekupuruzira ndiro kunoenderana nekumanikidzwa kwako.

Ichi chigadzirwa chakanakira kudzvinyirira nzvimbo dzekumanikidza kana kukwidziridzwa kwepamhepo kwekudzosera kumashure, zvinobudirira kugadzirisa kugadzirwa kwemishonga uye yemakemikari endasitiri uye pamhepo yekudzosera pamhepo, zvigadzirwa zvekugadzira zvinhu.

Zvishandiso

Chikafu & chinwiwa, kurapwa kwemvura, guruva kubvisa, pharmacy, makemikari, polymer, nezvimwe.

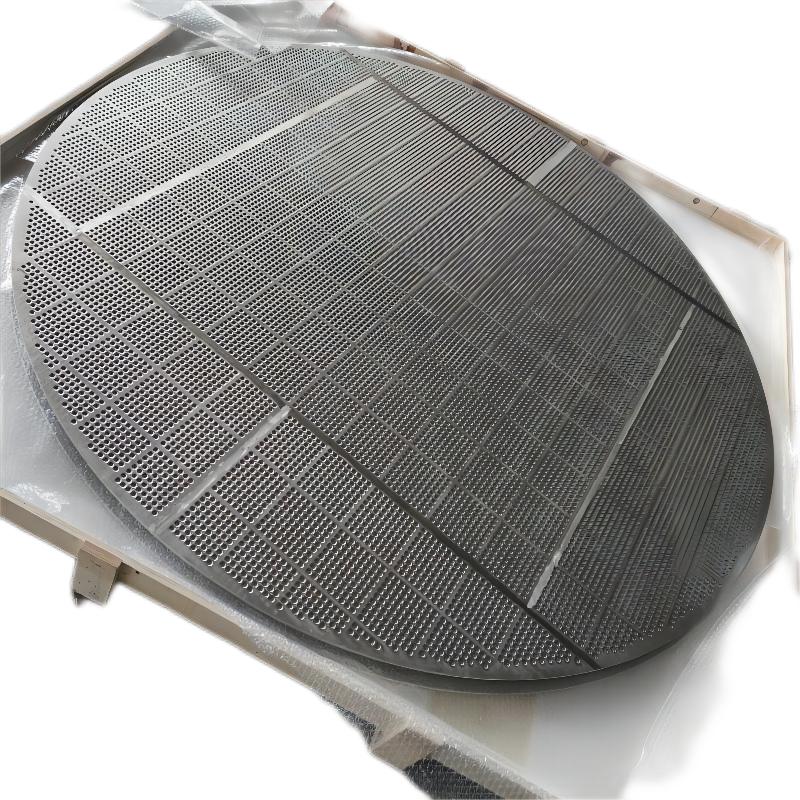

Plate yakasarudzika inotadza mesh rudzi rwemutengo mesh inotadza ndiro yemapuranga uye iyo base flat yakarukwa mesh pamwechete. Iyo yekurova ndiro inogona kusarudzwa mune dzakasiyana ukobvu zvinoenderana nezvinodiwa, uye iyo mambure ekuvhara maziso anogona kuve mumwe kana anopfuura matare. Nekuda kwekupuruzira ndiro sekutsigira, iyo mesheni ine simba rakanyanya rekumanikidza uye musimbe simba. Iko kutadza kweaviri kwete chete kune yakanaka yemhepo kuumbwa kweiyo flat yakarukwa mesh, asi zvakare ine simba rekuita renzvimbo yemapuranga. Inogona kuongororwa muCylindrical, Disc, Sheet uye Cone mafirita, inoshandiswa zvakanyanya mukurapwa kwemvura, chinwiwa, chokudya, metallurgy, yemakemikari uye maindasitiri emakemikari, nezvimwewo.

Plate yakasarudzika mesh zvinhu:

(1) Kunetseka kwakanaka uye yakakwirira michina simba. Nemhaka yekurova ndiro rutsigiro rwekutsigira, ine simba rakakura kwazvo rekumanikidza uye simba rekumanikidza pakati pemesadzi akatadza;

(2.

(3) Zviri nyore kuchenesa, iyo firita inotorwa, yakanyanya kukodzera kudzingwa;

.

.

Plate yakasarudzika inotakura mesh kushandisa:

(1) Zvigadzirwa zvinoshandiswa kuparadzira kutonhora munzvimbo dzakanyanyisa tembiricha.

.

.

.

.

(6) Catalyst Tsigiro Grille.

.